Download

Browse and Download Our Catalog for Reference

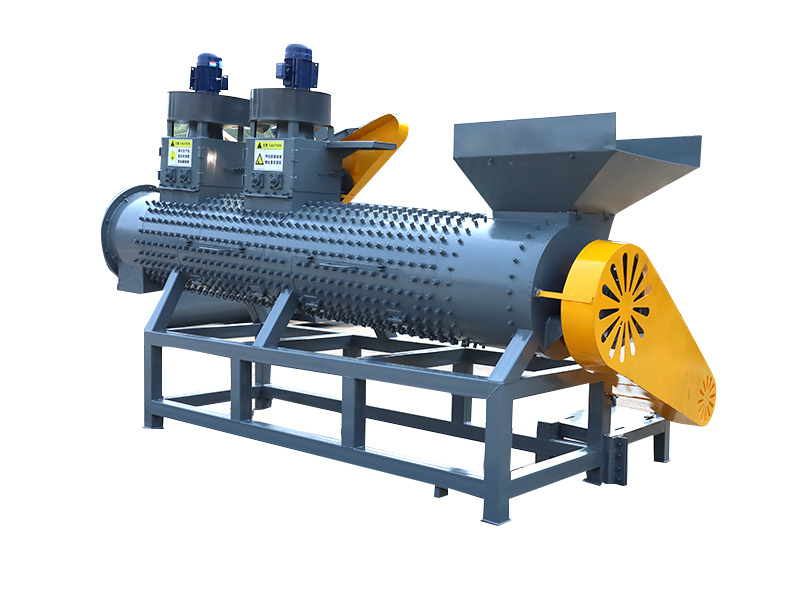

The use of high-speed friction cleaning machine

Materials from the feed port into the equipment through the high friction cleaninginside, will be attached to the bottle on the oil stains, not silicone and other strongattached to the removal of impurities, characterized by strong cleaning strength, waterconsumption is small, occupies an area of small, cost-effective.

File size:

11.7KB

Update time:

Jan 14,2025

The use of the whole net dryer

The equipment is widely used in PET/PE/PP/ABS/PS/PC and other sheet plasticdewatering, the water content of the sheet can be up to 2% or less, long service life,large output, no manual pickup,economical and practical. cost-effective.

File size:

763B

Update time:

Jan 14,2025

The use of emery de-labeling machine

To peel off the trademark paper on PET round bottles and bottle bricks, the cutterhead is made of extra-arge diamond/tungsten carbide, which is durable and wear-re-sistant, and doesn't hurt the bottles and bottle mouths, and the de-labeling machinehas been improved through continuous experiments, and the de-labeling rate of roundbottles can be up to more than 98%, and the de-labeling rate of bottle bricks can beup to more than 95%.

File size:

11.7KB

Update time:

Jan 14,2025

The use of shaftless drum screen

It is mainly used to screen out the impurities such as sediment, metal and bottlemouth material in bottle bricks, and at the same time to separate the large pieces ofplastics such as oil jugs and adhesive bottles, so as to lay a better foundation for thelater stages of bottle sorting,de-abeling, crushing and cleaning.

File size:

11.7KB

Update time:

Jan 14,2025

Purpose of the Open Charter

It is the first step in PET crushing and cleaning process, to break up the bottlebricks and tons of packages to do the preliminary impurity removal process, and atthe same time

File size:

763B

Update time:

Jan 14,2025