Unlocking Efficiency: How Delabeling Machines Enhance Production in Plastic Manufacturing

Unlocking Efficiency: How Delabeling Machines Enhance Production in Plastic Manufacturing

Table of Contents

1. Introduction to Delabeling Machines

2. The Importance of Delabeling in Production

2.1 Cost Efficiency through Delabeling

2.2 Time Savings with Delabeling Machines

3. Understanding the Delabeling Process

3.1 How De

Jun 13,2025

Unlocking Efficiency: How Delabeling Machines Enhance Production in Plastic Manufacturing

Table of Contents

- 1. Introduction to Delabeling Machines

- 2. The Importance of Delabeling in Production

- 3. Understanding the Delabeling Process

- 4. Types of Delabeling Machines for Plastic Processing

- 5. Key Benefits of Using Delabeling Machines

- 6. Challenges in Delabeling and How to Overcome Them

- 7. The Future of Delabeling Machines in Manufacturing

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Delabeling Machines

In the fast-paced world of plastic manufacturing, efficiency is paramount. With the constant pressure to reduce costs and increase production rates, manufacturers are turning to innovative solutions to optimize their processes. One such solution is the **delabeling machine**. These specialized machines are designed to remove labels from plastic products efficiently, paving the way for enhanced recycling and reuse.

2. The Importance of Delabeling in Production

Delabeling is not merely a secondary consideration; it is a crucial step in the production process that can significantly impact the overall sustainability and cost-effectiveness of manufacturing operations.

2.1 Cost Efficiency through Delabeling

Removing labels from plastic products before recycling is essential for preserving the quality of the recycled material. Labels can introduce contaminants that compromise the integrity of the recycled plastic. By investing in delabeling machines, manufacturers can salvage valuable materials, thus reducing the costs associated with purchasing virgin plastics.

2.2 Time Savings with Delabeling Machines

Time is money in manufacturing. Traditional delabeling methods can be labor-intensive and time-consuming, leading to production bottlenecks. Delabeling machines streamline this process, allowing manufacturers to focus on core production activities while efficiently handling label removal.

3. Understanding the Delabeling Process

A clear understanding of the delabeling process is vital for manufacturers looking to implement these machines effectively.

3.1 How Delabeling Machines Work

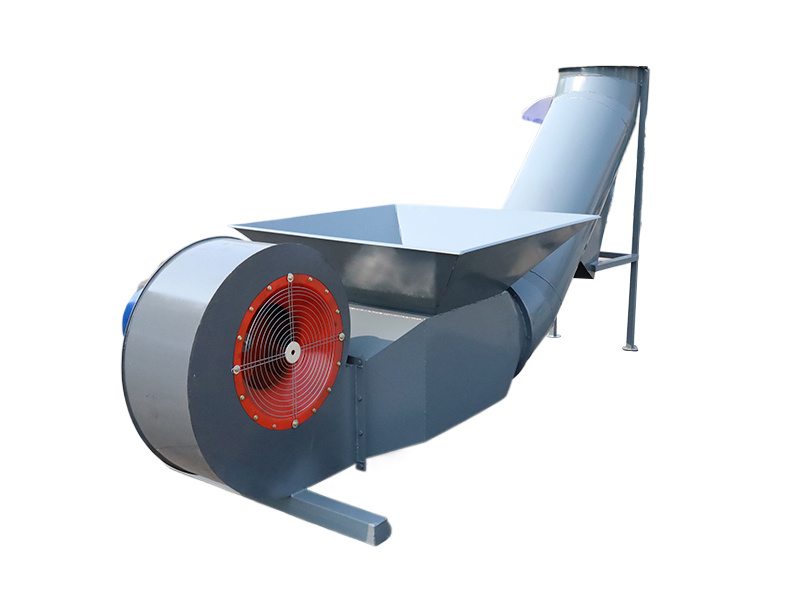

Delabeling machines utilize a combination of mechanical and chemical processes to remove labels. The machine’s mechanism typically involves feeding plastic products into a chamber where the labels are detached using various methods such as abrasion, heat, or solvent application.

3.2 Advanced Technology in Delabeling

Recent advancements in technology have led to the development of more sophisticated delabeling machines. These machines are equipped with sensors and automation features that enhance accuracy and speed, ensuring that labels are removed without damaging the underlying plastic.

4. Types of Delabeling Machines for Plastic Processing

Manufacturers can choose from several types of delabeling machines, depending on their specific production needs.

4.1 Manual Delabeling Machines

Manual delabeling machines are cost-effective solutions ideal for small-scale operations. They require human intervention to operate but can be efficient for businesses that do not handle large volumes of plastic products.

4.2 Automatic Delabeling Machines

On the other hand, automatic delabeling machines are designed for high-volume production. They operate with minimal human intervention and can process hundreds or thousands of units per hour, making them suitable for larger manufacturing facilities.

5. Key Benefits of Using Delabeling Machines

The advantages of employing delabeling machines extend beyond mere efficiency.

5.1 Sustainability and Environmental Impact

By enhancing the efficiency of the recycling process, delabeling machines contribute to sustainability. They help reduce plastic waste in landfills, promote the circular economy, and facilitate the reuse of materials, aligning with global sustainability goals.

5.2 Quality Control Enhancements

Delabeling machines ensure that plastic materials are free from contaminants. This purity is essential for maintaining the quality of recycled products, which can directly affect the end product's performance and marketability.

6. Challenges in Delabeling and How to Overcome Them

Despite their benefits, manufacturers may encounter challenges when integrating delabeling machines into their processes.

One common challenge is the variation in label types and adhesives used in plastic products. Different materials may require different delabeling techniques. Manufacturers should invest in versatile machines that can adapt to various label types or have multiple machines to accommodate specific needs.

Another challenge is the initial cost of investment. While delabeling machines can lead to long-term savings, the upfront costs can be significant. Manufacturers can overcome this by conducting a thorough cost-benefit analysis that highlights the long-term savings associated with efficiency and material recovery.

7. The Future of Delabeling Machines in Manufacturing

The future of delabeling machines is promising. With advancements in automation, artificial intelligence, and machine learning, future delabeling machines will likely become even more efficient and user-friendly. This evolution will enable manufacturers to handle increasingly complex products while maintaining high standards of quality and efficiency.

Additionally, as regulatory pressures mount for sustainable practices, delabeling machines will play an integral role in helping manufacturers comply with environmental standards and expectations.

8. Conclusion

Delabeling machines are vital in modern plastic manufacturing, driving efficiency and sustainability. By automating the label removal process, these machines not only save time and reduce costs but also contribute to higher quality recycled materials. As manufacturers continue to seek innovative solutions to improve their production processes, delabeling machines will undoubtedly remain at the forefront of this evolution, paving the way for a more sustainable future.

9. Frequently Asked Questions

1. What types of products can be delabeled using these machines?

Delabeling machines can process a wide variety of plastic products, including bottles, containers, and other plastic items with labels.

2. How do delabeling machines improve recycling rates?

By removing labels efficiently, these machines prevent contamination of the recycled materials, leading to higher quality output and increased recycling rates.

3. Are there any maintenance requirements for delabeling machines?

Yes, regular maintenance is essential to keep delabeling machines operating efficiently. This includes cleaning, inspections, and timely repairs as needed.

4. How can I choose the right delabeling machine for my business?

Consider factors such as production volume, types of labels, and budget when selecting a delabeling machine. Consulting with a manufacturer can also provide insights tailored to your needs.

5. Can delabeling machines handle different types of adhesives?

Yes, some delabeling machines are designed to handle a variety of adhesives. However, it’s essential to choose a machine that suits the specific types of labels used in your production process.

By understanding the functionality and benefits of delabeling machines, plastic manufacturers can enhance their production processes, leading to greater efficiency and sustainability in the industry.

TAG:

Contact Us

E-mail :

Phone/WhatsApp:

Address:

Shunping, Baoding City, Hebei Province