Understanding Delabeling Machines: A Key Component in Plastic Recycling

Delabeling machines are specialized devices designed to remove labels, adhesives, and other contaminants from plastic containers and products. In the manufacturing and processing sector, these machines serve a vital function, ensuring that recycled materials meet quality standards for subsequent reuse or recycling. The delabeling process is essential as contaminants can hinder the recycling proces

Sep 05,2025

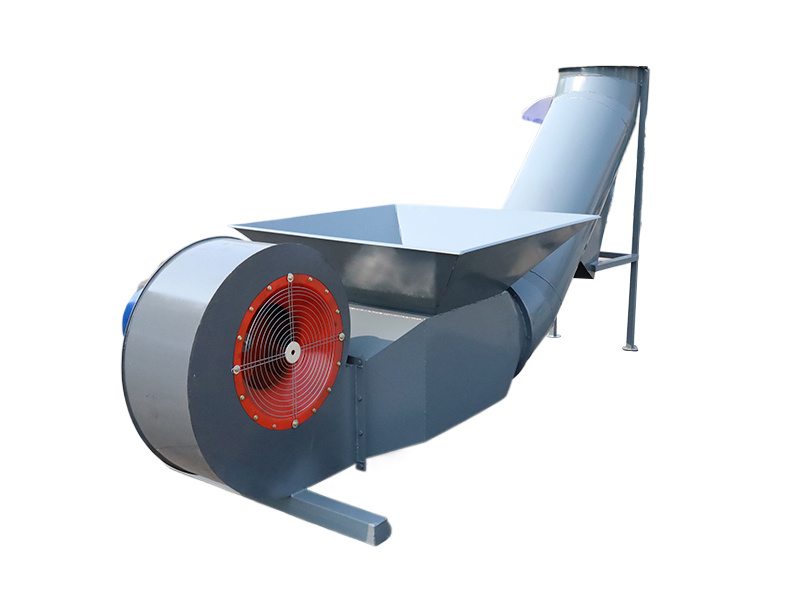

Delabeling machines are specialized devices designed to remove labels, adhesives, and other contaminants from plastic containers and products. In the manufacturing and processing sector, these machines serve a vital function, ensuring that recycled materials meet quality standards for subsequent reuse or recycling. The delabeling process is essential as contaminants can hinder the recycling process and decrease the quality of the final recycled product.

The need for delabeling machines has grown alongside the increasing emphasis on environmental sustainability and responsible waste management. As industries and consumers shift towards a circular economy, effective recycling processes become paramount. Delabeling machines contribute to this by preparing plastic materials for recycling, making them cleaner and more suitable for reprocessing into new products.

In operation, delabeling machines often employ various technologies such as mechanical scraping, thermal processes, or chemical treatments to effectively remove labels. The choice of technology can depend on the type of plastic, the kind of labels used, and the intended outcome. For example, certain materials may respond better to heat, while others may require more aggressive mechanical removal methods.

In addition to their functional benefits, delabeling machines can also enhance the efficiency of recycling operations. By automating the label removal process, manufacturers can significantly reduce labor costs and increase throughput. This leads to a more cost-effective recycling operation, allowing businesses to allocate resources more efficiently and improve overall productivity.

Furthermore, the integration of delabeling machines into recycling workflows is increasingly seen as a best practice. They help ensure compliance with recycling regulations and standards, which can vary by region and impact the marketability of recycled plastics. By utilizing delabeling machines, manufacturers can better position themselves in a competitive market that increasingly values sustainability and responsible practices.

In summary, delabeling machines are integral to the plastic processing industry, enabling effective recycling by removing labels and contaminants from plastic products. Their ability to boost efficiency, contribute to regulatory compliance, and enhance the quality of recycled materials makes them a valuable asset in the journey towards a sustainable future. As the recycling landscape continues to evolve, these machines will undoubtedly play a pivotal role in shaping how plastics are processed and recycled.

The need for delabeling machines has grown alongside the increasing emphasis on environmental sustainability and responsible waste management. As industries and consumers shift towards a circular economy, effective recycling processes become paramount. Delabeling machines contribute to this by preparing plastic materials for recycling, making them cleaner and more suitable for reprocessing into new products.

In operation, delabeling machines often employ various technologies such as mechanical scraping, thermal processes, or chemical treatments to effectively remove labels. The choice of technology can depend on the type of plastic, the kind of labels used, and the intended outcome. For example, certain materials may respond better to heat, while others may require more aggressive mechanical removal methods.

In addition to their functional benefits, delabeling machines can also enhance the efficiency of recycling operations. By automating the label removal process, manufacturers can significantly reduce labor costs and increase throughput. This leads to a more cost-effective recycling operation, allowing businesses to allocate resources more efficiently and improve overall productivity.

Furthermore, the integration of delabeling machines into recycling workflows is increasingly seen as a best practice. They help ensure compliance with recycling regulations and standards, which can vary by region and impact the marketability of recycled plastics. By utilizing delabeling machines, manufacturers can better position themselves in a competitive market that increasingly values sustainability and responsible practices.

In summary, delabeling machines are integral to the plastic processing industry, enabling effective recycling by removing labels and contaminants from plastic products. Their ability to boost efficiency, contribute to regulatory compliance, and enhance the quality of recycled materials makes them a valuable asset in the journey towards a sustainable future. As the recycling landscape continues to evolve, these machines will undoubtedly play a pivotal role in shaping how plastics are processed and recycled.

TAG:

Contact Us

E-mail :

Phone/WhatsApp:

Address:

Shunping, Baoding City, Hebei Province