How Delabeling Machines Improve Material Recovery Rates: A Comprehensive Guide

How Delabeling Machines Improve Material Recovery Rates

Table of Contents

Introduction to Delabeling Machines

Understanding Material Recovery Rates

The Role of Delabeling Machines in Recycling

Technology Behind Delabeling Machines

Benefits of Using Delabeling Machines

Applications of Delabeling Machines in the Industry

Choosing the Right Delabeling Machine for Your Nee

Nov 19,2025

How Delabeling Machines Improve Material Recovery Rates

Table of Contents

- Introduction to Delabeling Machines

- Understanding Material Recovery Rates

- The Role of Delabeling Machines in Recycling

- Technology Behind Delabeling Machines

- Benefits of Using Delabeling Machines

- Applications of Delabeling Machines in the Industry

- Choosing the Right Delabeling Machine for Your Needs

- The Future of Delabeling Technology

- Frequently Asked Questions

- Conclusion

Introduction to Delabeling Machines

Delabeling machines play a pivotal role in the plastic recycling industry. As manufacturers strive to improve their sustainability practices, these machines have emerged as a key technology for enhancing material recovery rates. By removing labels and contaminants from plastic waste, delabeling machines ensure that the recycled material is of higher quality and purer, which in turn boosts the overall efficiency of recycling processes.

Understanding Material Recovery Rates

Material recovery rates refer to the percentage of waste material that is successfully diverted from landfills and processed for reuse and recycling. In the realm of plastic recycling, high recovery rates are crucial. They not only contribute to environmental sustainability but also reduce the demand for virgin materials. The importance of improving these rates cannot be overstated, especially in an era where plastic waste is a growing concern.

Factors Influencing Material Recovery Rates

Several factors influence material recovery rates, including:

1. **Quality of Material**: Contaminants like labels, adhesives, and leftover residues can significantly reduce the quality of recycled plastics.

2. **Technology Used**: Advanced recycling technologies, such as delabeling machines, enhance the separation and processing of materials.

3. **Market Demand**: The demand for recycled materials affects investment in recycling technologies and processes.

The Role of Delabeling Machines in Recycling

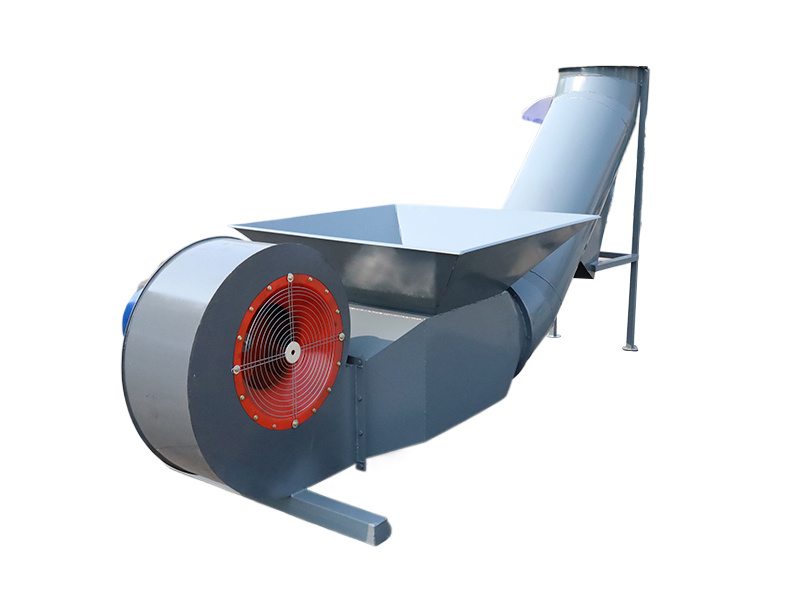

Delabeling machines are designed to efficiently eliminate labels from plastic containers, bottles, and other products. This process is vital, as labels often contain adhesives and synthetic materials that can compromise the quality of the recycled output. By integrating delabeling technology into recycling operations, manufacturers can significantly improve the purity and value of recycled materials.

How Delabeling Machines Operate

Delabeling machines typically employ various methods to remove labels, including:

- **Mechanical Scraping**: Using blades or brushes to scrape labels off surfaces.

- **Thermal Methods**: Applying heat to soften adhesives for easier removal.

- **Chemical Solutions**: Utilizing solvents that effectively dissolve adhesives without harming the underlying plastic.

Each machine may use a combination of these methods, ensuring optimal performance depending on the type of label and container material.

Technology Behind Delabeling Machines

The technology used in delabeling machines has evolved significantly. Modern machines are equipped with advanced features that enhance their efficiency and effectiveness, such as:

- **Automation**: Automating the delabeling process increases throughput and reduces labor costs.

- **Sensors and Cameras**: These technologies help in identifying and sorting different types of plastics, ensuring that the right materials are processed accordingly.

- **Energy Efficiency**: Newer models are designed with energy-saving features that reduce their environmental footprint.

Types of Delabeling Machines

Delabeling machines come in various types, tailored to different processing needs:

1. **Batch Delabeling Machines**: Suitable for smaller operations where material is processed in batches.

2. **Continuous Delabeling Systems**: Ideal for larger facilities that require continuous processing of materials.

Benefits of Using Delabeling Machines

The implementation of delabeling machines brings several benefits to recycling operations, including:

1. Enhanced Material Purity

By effectively removing labels and contaminants, delabeling machines enhance the purity of recycled plastics. This leads to higher quality end products, which are more appealing to manufacturers and consumers alike.

2. Increased Recovery Rates

Improved material quality translates to higher recovery rates. When labels are removed efficiently, more plastic waste can be processed and turned into reusable material.

3. Cost-Effectiveness

Investing in delabeling technology can reduce overall processing costs by streamlining operations and minimizing waste. Higher recovery rates mean more materials can be sold, positively impacting profitability.

4. Environmental Impact

By improving recycling processes, delabeling machines contribute to reducing the volume of plastic waste in landfills. This aligns with global sustainability initiatives aimed at minimizing environmental impact.

5. Compliance with Regulations

Many jurisdictions impose strict regulations regarding the recycling of plastics. Delabeling machines facilitate compliance by ensuring that contaminants are removed before recycling, avoiding penalties and enhancing operational credibility.

Applications of Delabeling Machines in the Industry

Delabeling machines are versatile tools used across various sectors that handle plastic waste, including:

1. Beverage Industry

In the beverage industry, delabeling machines are essential for processing PET bottles. Efficient label removal enhances the quality of recycled PET, which is highly sought after for creating new bottles and containers.

2. Food Industry

Food packaging often presents challenges due to adhesives and residues. Delabeling machines help ensure that packaging materials can be recycled without compromising safety and quality.

3. Household Products

Plastic containers from household products often have labels that must be removed before recycling. Delabeling machines streamline this process, making it easier for manufacturers to recycle materials.

4. Industrial Applications

In industrial settings, delabeling machines are used to process a variety of plastic waste from different sources, enhancing overall material recovery.

Choosing the Right Delabeling Machine for Your Needs

When selecting a delabeling machine, consider the following factors:

1. Type of Plastic

Different plastics require different delabeling approaches. Ensure the machine you choose is compatible with the types of materials you process.

2. Volume of Material

Evaluate your processing volume. Larger operations may benefit from continuous delabeling systems, while smaller facilities might find batch machines adequate.

3. Budget

Consider the return on investment. While initial costs may be higher for advanced machines, the long-term savings from increased recovery rates can justify the expense.

4. Maintenance and Support

Choose a manufacturer that offers reliable support and maintenance services, ensuring your machine operates efficiently over time.

The Future of Delabeling Technology

As the push for sustainability continues to grow, the future of delabeling technology looks promising. Innovations in automation, energy efficiency, and material processing techniques will drive the development of even more effective delabeling machines. Additionally, as recycling regulations become stricter, the demand for efficient delabeling solutions will likely increase, further enhancing the role of these machines in the recycling industry.

Frequently Asked Questions

1. What types of labels can delabeling machines remove?

Delabeling machines can typically remove a variety of labels, including paper, plastic, and adhesive labels, depending on the technology used.

2. How does delabeling impact the recycling process?

By removing labels and contaminants, delabeling machines improve the purity and quality of recycled materials, which enhances overall recycling efficiency.

3. Are delabeling machines suitable for small businesses?

Yes, small businesses can benefit from delabeling machines, especially batch models that are designed for lower processing volumes.

4. How often should delabeling machines be serviced?

Regular maintenance is essential for optimal performance. It's recommended to follow the manufacturer's guidelines, typically involving routine checks and servicing every few months.

5. What is the ROI on investing in delabeling machines?

The return on investment can vary, but many businesses see improved recovery rates and cost savings within the first year of operation, depending on the scale of their recycling efforts.

Conclusion

Delabeling machines are critical to enhancing material recovery rates in the plastic recycling process. By efficiently removing labels and contaminants, these machines improve the quality of recycled materials, leading to higher recovery rates and significant environmental benefits. As industries continue to seek sustainable solutions, the role of delabeling technology will only become more important. Investing in this technology not only supports compliance with regulations but also contributes to a greener future by maximizing the potential of recycled plastics.

TAG:

Contact Us

E-mail :

Phone/WhatsApp:

Address:

Shunping, Baoding City, Hebei Province