Understanding Delabeling Machines: Essential Tools for Efficient Plastic Processing

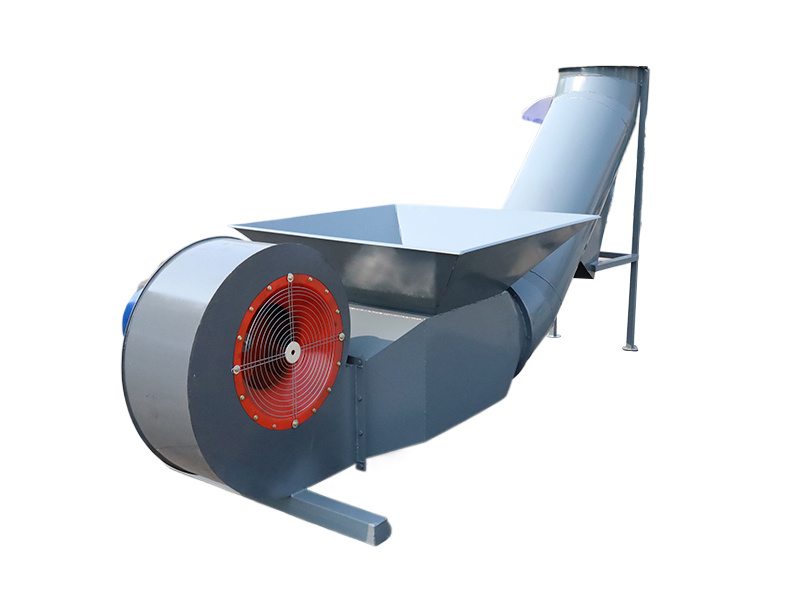

Delabeling machines play a crucial role in the plastic processing sector, particularly for businesses focusing on recycling and reusing materials. These specialized machines are designed to efficiently remove labels from plastic containers and other products, increasing the value of the recovered material and facilitating a smoother recycling process.

The primary purpose of a delabeling machine is

Nov 16,2025

Delabeling machines play a crucial role in the plastic processing sector, particularly for businesses focusing on recycling and reusing materials. These specialized machines are designed to efficiently remove labels from plastic containers and other products, increasing the value of the recovered material and facilitating a smoother recycling process.

The primary purpose of a delabeling machine is to eliminate adhesives, labels, and any contaminants that may hinder the recycling process. In an era where sustainability is paramount, the efficient removal of labels ensures that the plastic material can be processed without compromising the quality or integrity of the final product. This is particularly important as consumers and manufacturers alike are increasingly conscious of their environmental impact.

Delabeling machines come in various designs and sizes, accommodating different types of containers and materials. Their operation can typically be categorized into mechanical, thermal, and chemical methods. Mechanical delabeling often involves the use of friction or scraping techniques to dislodge labels, whereas thermal methods utilize heat to soften adhesives, making them easier to remove. Chemical delabeling involves the application of solvents that dissolve adhesives without damaging the underlying plastic. Choosing the right method depends on the specific needs of the operation, the types of labels used, and the desired outcome.

In addition to improving the quality of recycled materials, delabeling machines can significantly enhance operational efficiency. By automating the label removal process, businesses can reduce labor costs and minimize the time spent on manual sorting and cleaning. This not only speeds up production rates but also allows workers to focus on higher-value tasks within the manufacturing process.

Moreover, the integration of delabeling machines into a production line can contribute to a company's compliance with environmental regulations. Many regions are implementing stricter guidelines on recycling practices, and businesses that utilize delabeling technology can better align with these standards. This proactive approach not only benefits the environment but also enhances a company's reputation as a responsible manufacturer.

Investing in a delabeling machine is a strategic move for any plastic processing operation aiming to improve recycling outcomes and operational efficiency. By understanding the technology and its benefits, manufacturers can make informed decisions that align with their sustainability goals. As the demand for recycled materials continues to rise, the role of delabeling machines will become increasingly significant in the quest for a circular economy.

The primary purpose of a delabeling machine is to eliminate adhesives, labels, and any contaminants that may hinder the recycling process. In an era where sustainability is paramount, the efficient removal of labels ensures that the plastic material can be processed without compromising the quality or integrity of the final product. This is particularly important as consumers and manufacturers alike are increasingly conscious of their environmental impact.

Delabeling machines come in various designs and sizes, accommodating different types of containers and materials. Their operation can typically be categorized into mechanical, thermal, and chemical methods. Mechanical delabeling often involves the use of friction or scraping techniques to dislodge labels, whereas thermal methods utilize heat to soften adhesives, making them easier to remove. Chemical delabeling involves the application of solvents that dissolve adhesives without damaging the underlying plastic. Choosing the right method depends on the specific needs of the operation, the types of labels used, and the desired outcome.

In addition to improving the quality of recycled materials, delabeling machines can significantly enhance operational efficiency. By automating the label removal process, businesses can reduce labor costs and minimize the time spent on manual sorting and cleaning. This not only speeds up production rates but also allows workers to focus on higher-value tasks within the manufacturing process.

Moreover, the integration of delabeling machines into a production line can contribute to a company's compliance with environmental regulations. Many regions are implementing stricter guidelines on recycling practices, and businesses that utilize delabeling technology can better align with these standards. This proactive approach not only benefits the environment but also enhances a company's reputation as a responsible manufacturer.

Investing in a delabeling machine is a strategic move for any plastic processing operation aiming to improve recycling outcomes and operational efficiency. By understanding the technology and its benefits, manufacturers can make informed decisions that align with their sustainability goals. As the demand for recycled materials continues to rise, the role of delabeling machines will become increasingly significant in the quest for a circular economy.

TAG:

Contact Us

E-mail :

Phone/WhatsApp:

Address:

Shunping, Baoding City, Hebei Province