Unlocking Efficiency in Plastic Recycling: The Role of Delabeling Machines

In the realm of plastic processing machinery, delabeling machines have garnered considerable attention for their pivotal role in enhancing the efficiency of recycling operations. These specialized machines are designed to remove labels and adhesives from plastic containers, a critical step in preparing materials for further processing. Understanding the technical aspects and operational benefits o

Nov 28,2025

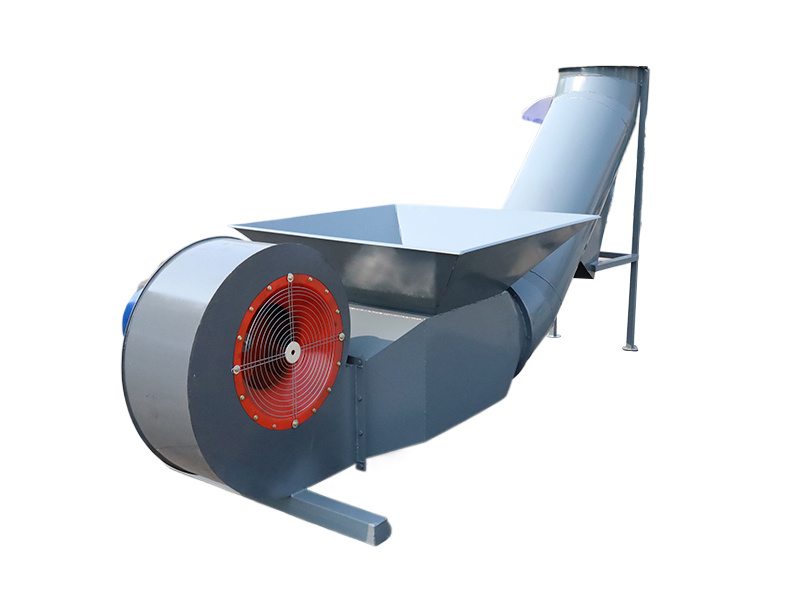

In the realm of plastic processing machinery, delabeling machines have garnered considerable attention for their pivotal role in enhancing the efficiency of recycling operations. These specialized machines are designed to remove labels and adhesives from plastic containers, a critical step in preparing materials for further processing. Understanding the technical aspects and operational benefits of delabeling machines can significantly impact the overall effectiveness of plastic recycling initiatives.

Delabeling machines operate through a combination of mechanical action and advanced technology. They utilize methods such as friction, steam, or chemical solvents to detach labels from various types of plastic substrates. This process not only ensures that the plastics are clean and free from contaminants but also maximizes the quality of the recycled material. Clean plastics are essential for producing high-grade recycled products, which can be used in various applications, thereby promoting a circular economy.

One of the key benefits of delabeling machines is their ability to enhance operational efficiency. By automating the label removal process, these machines reduce manual labor and the time taken to prepare plastic for recycling. This efficiency translates into higher throughput in recycling facilities, enabling processors to handle larger volumes of plastic waste more effectively. Consequently, businesses can achieve better scalability and sustainability in their operations.

Moreover, the integration of delabeling machines in recycling lines contributes to improved safety standards. Manual label removal can expose workers to hazardous materials and chemicals, particularly when dealing with adhesives. By utilizing specialized machinery, the risk of workplace injuries is significantly reduced, creating a safer working environment.

Another important aspect is the environmental impact of delabeling machines. By facilitating the recycling of plastics, these machines play a crucial role in reducing the amount of plastic waste that ends up in landfills and oceans. The global push towards sustainability and environmental conservation makes delabeling machines an integral part of modern plastic processing operations. They not only support compliance with environmental regulations but also align with corporate social responsibility goals aimed at reducing ecological footprints.

In summary, delabeling machines are essential for the efficient processing of plastics in the recycling industry. They streamline operations, enhance safety, and contribute to environmental sustainability. As the demand for eco-friendly practices continues to grow, investing in advanced delabeling technology is a strategic move for businesses looking to optimize their plastic recycling processes. Understanding the functionalities and advantages of delabeling machines is key to leveraging their potential in achieving a more sustainable manufacturing ecosystem.

Delabeling machines operate through a combination of mechanical action and advanced technology. They utilize methods such as friction, steam, or chemical solvents to detach labels from various types of plastic substrates. This process not only ensures that the plastics are clean and free from contaminants but also maximizes the quality of the recycled material. Clean plastics are essential for producing high-grade recycled products, which can be used in various applications, thereby promoting a circular economy.

One of the key benefits of delabeling machines is their ability to enhance operational efficiency. By automating the label removal process, these machines reduce manual labor and the time taken to prepare plastic for recycling. This efficiency translates into higher throughput in recycling facilities, enabling processors to handle larger volumes of plastic waste more effectively. Consequently, businesses can achieve better scalability and sustainability in their operations.

Moreover, the integration of delabeling machines in recycling lines contributes to improved safety standards. Manual label removal can expose workers to hazardous materials and chemicals, particularly when dealing with adhesives. By utilizing specialized machinery, the risk of workplace injuries is significantly reduced, creating a safer working environment.

Another important aspect is the environmental impact of delabeling machines. By facilitating the recycling of plastics, these machines play a crucial role in reducing the amount of plastic waste that ends up in landfills and oceans. The global push towards sustainability and environmental conservation makes delabeling machines an integral part of modern plastic processing operations. They not only support compliance with environmental regulations but also align with corporate social responsibility goals aimed at reducing ecological footprints.

In summary, delabeling machines are essential for the efficient processing of plastics in the recycling industry. They streamline operations, enhance safety, and contribute to environmental sustainability. As the demand for eco-friendly practices continues to grow, investing in advanced delabeling technology is a strategic move for businesses looking to optimize their plastic recycling processes. Understanding the functionalities and advantages of delabeling machines is key to leveraging their potential in achieving a more sustainable manufacturing ecosystem.

TAG:

Contact Us

E-mail :

Phone/WhatsApp:

Address:

Shunping, Baoding City, Hebei Province